Carbide Products, Inc.

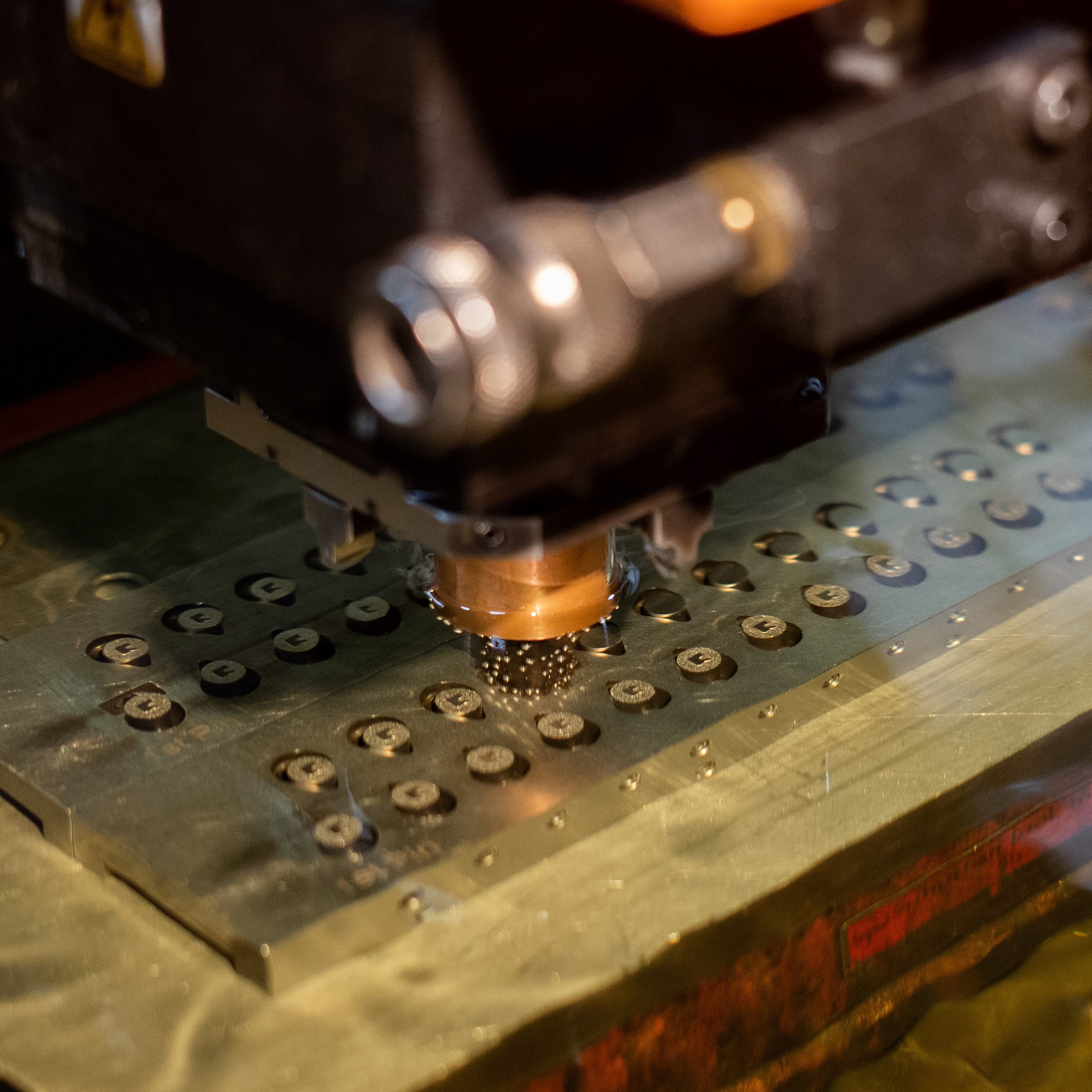

Where Craftsmanship and Technology Meet

Kentucky’s Premium Tool and Die Shop

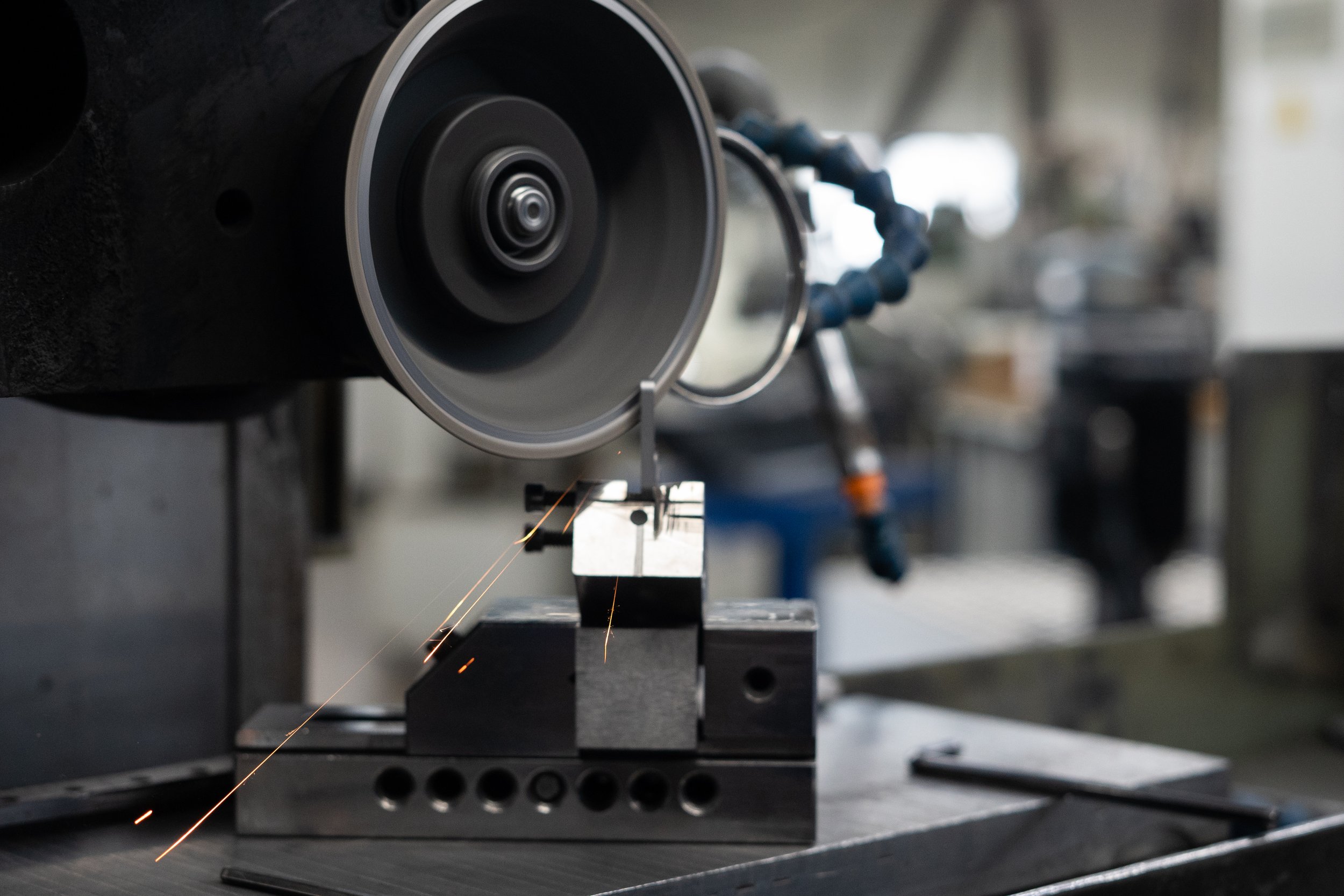

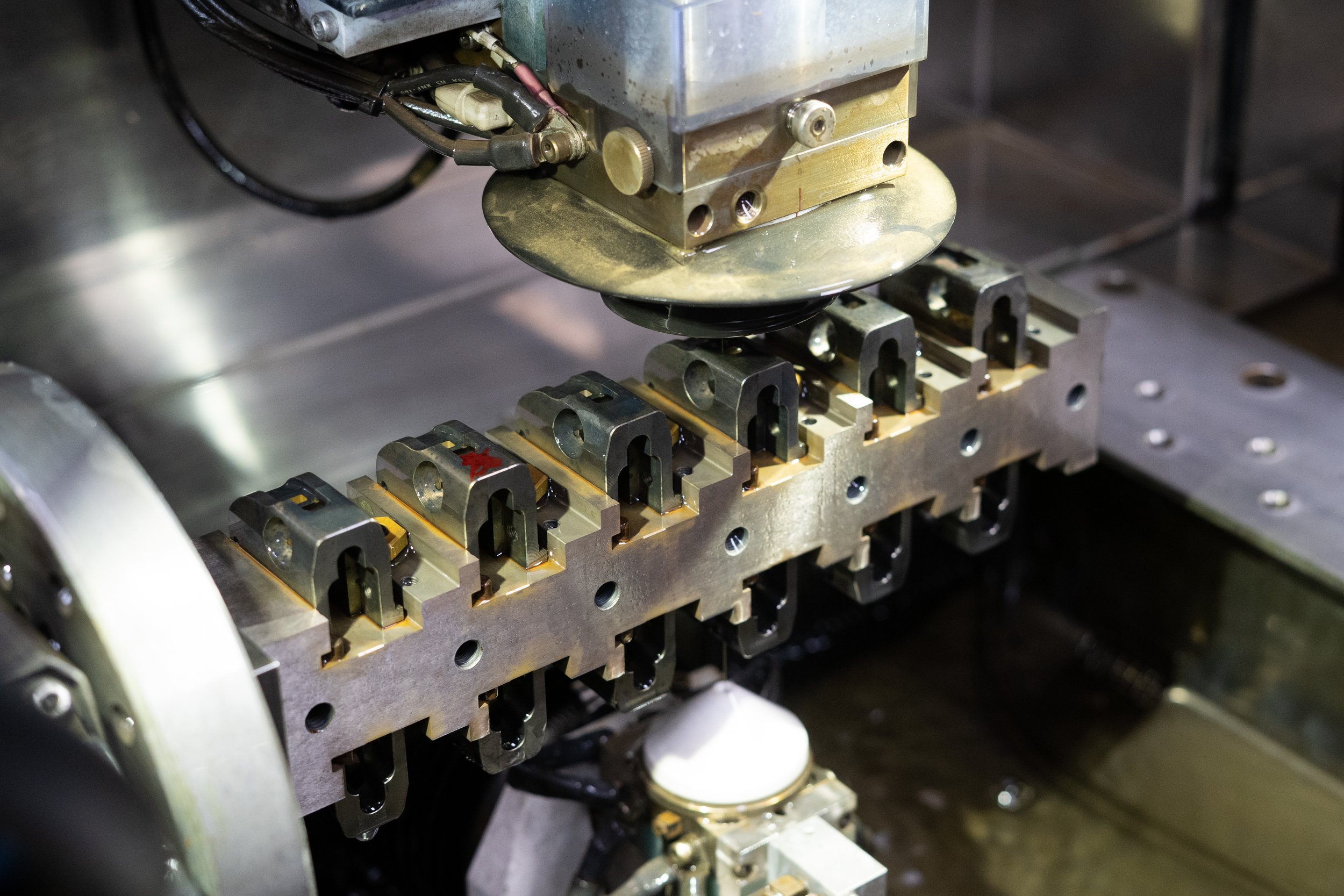

At Carbide Products, our mission is to deliver precision-manufactured solutions that exceed our clients’ expectations. Through a relentless commitment to craftsmanship, innovation, and exceptional customer service, we aim to be the trusted partner for your business. With a focus on constant improvement, we strive to contribute to our partners’ success by providing them with the highest caliber of CNC machined tooling and components. Our dedication to excellence drives us to continually push the limits of our industry.

30+

Countries Serviced

14

Industries Serviced

Our Team

At Carbide Products, our employees are our greatest asset. We employ highly skilled and experienced machinist in every discipline. With over 80 years in business our senior employees have seen it all. Alongside our next generation of apprentices we solve the most complex problems with dedication and creativity.